What

is the Rodster®?

© Copyright Caroselli.

No images or text located anywhere on this site may be reused

or republished without expressed written permission from Rodster,

Inc., d.b.a.: Caroselli Design. The Rodster Street Rod design

is protected by

U.S. Patent # D450,284.

"Rodster®" is a registered

trademark of Caroselli Design. |

What is Kit Car Magazine saying about the Rodster® Street Rod?

Kit

Car Magazine

Kit

Car Magazine

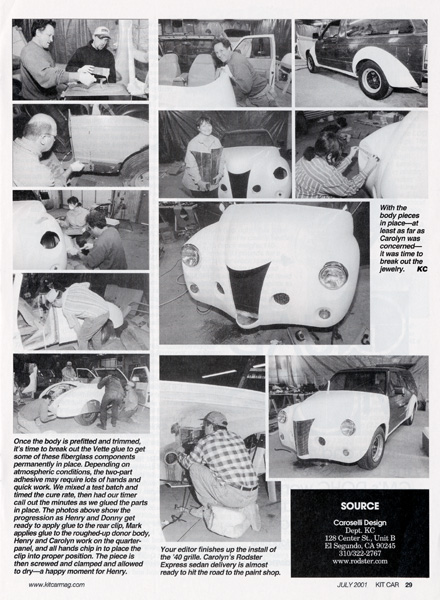

The Tri-Rodster Project

text by Jim Youngs

photos by Kaci Colton, Mark Wiley, Kerri Wiley, Carolyn Youngs, Jim Youngs

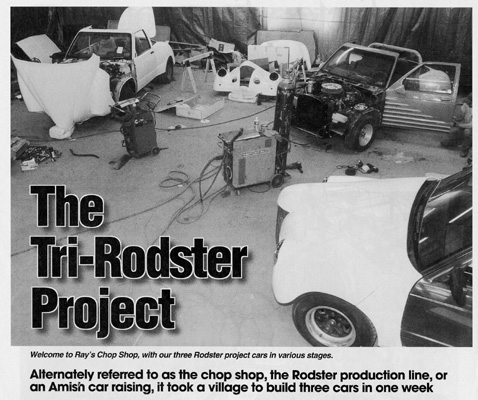

Alternately referred to as the chop shop, the Rodster production line, or an Amish car raising, it took a village to build three cars in one week.

It all began quite innocently enough, as many car-project ideas germinate around here. Bench-racing sessions typically generate lots of "why couldn't we" discussions, and a few of them eventually lead to neat projects and great stories. Few of these ideas in my experience, however, are as ambitious and span as long a time period as the cool buildup project I'm about to outline here.

Though I've been involved with hotrods since high school, I credit my buddy Mark Wiley with getting me really involved. About the time I started freelance writing for Kit Car, Mark dragged me along to the NSRA Rocky Mountain Nationals in Pueblo, Colorado, in the back of his well-traveled '39 Dodge rod. Mark, like most rodders, is always discussing future projects and is never at a loss for considering that next cool car, much to the chagrin of his tolerant spouse.

Mark joined Henry Caroselli (creator of the S-10 Blazer-based Rodster) and me for part of the Hot Rod Power Tour in 1997. Of course, the topic of conversation invariably got around to future projects. After a couple days hanging with Henry and his long-haul Rodster, Mark was hooked, particularly when he learned the Rodster kit would also easily fit a Typhoon donor. The wheels were already in motion, and Mark quickly became a Rodster prophet, spreading the word to all who would listen. He even bought a Typhoon ostensibly on which to build a hot Rodster, but ultimately decided against cutting it up. His desire to build a Rodster didn't wane, however. After more than a year of thinking about it, he called me out of the blue one day and asked what I thought about him and a bunch of his apostles building several Rodsters all at the same time. I agreed it would make a good story, and away Mark went with my encouragement.

Considerably more time passed, and Mark continued to talk about the multi-Rodster buildup, but time, family, and financial commitments kept the project in the talking stage. Last summer, Mark called again and asked what I thought about a two-car build. He had apparently convinced two of his business associates to buy into the idea, one of whom dropped out unexpectedly. I recall my comment to be, "Yeah, that would still be a cool story, but three cars might just make it a cover story," or something like that. In the meantime, Mark and son Kent found an S-10 donor in Kansas, towed it to Texas, and ordered their Rodster kit from Henry. Likewise, Ray Yauk, an associate of Mark's, ordered his Deluxe Rodster kit and found a nice GMC S-15 Jimmy in his hometown of Buffalo, Oklahoma. They would still work toward finding someone to play third string. Mark exhausted his contacts and approached me once again with a new idea he had cooked up with the Rodsterfather: The three of us would chip in parts and pieces of the third car, do the story, sell that car at the end of the project, and recoup our individual investments.

Having a considerable investment in a bunch of my own project cars, I was pondering this latest idea when my wife, Carolyn, asked at dinner one evening out, "How's Mark's Rodster project coming along?" I explained where the project stood and Mark's latest idea. She then began to ask some detailed questions -- the answers to which would provide much more information about kit cars than she usually cares to know. "How much would it cost to build this third Rodster?" "How long would it take?" "Would Henry be there to help?" "How hard is it to put the kit together?" and on and on.

I only had one question of her: "Why do you want to know all that?" Her short answer centered on wanting to figure out what this attraction between men and custom cars was all about. She also said she wanted to learn more about my passion for cars, and then confessed that she had loved the Rodster ever since I brought one of Henry's demonstrators home for a weekend of cruising. She had several other compelling reasons as well, but I must have missed some of them as I was drying my watery eyes (surely caused by the smoky restaurant atmosphere).

Now the story was taking on an entirely new personality and much wider appeal. Carolyn committed to building the third car, as well as volunteering it to be the official Kit Car ride for the 2001 Power Tour, on which she would join the Long Haul Gang from Detroit, Michigan, to San Bernardino, California.

We ordered the kit and began Mountain states search for a two-wheel-drive S-10 donor on which to build a Rodster Express sedan delivery model. Guess what -- there's not much call for 2WD trucks on this side of the Rockies, so we made a special trip to California -- donor-car mecca -- where we found a one-owner beauty that had been well cared for.

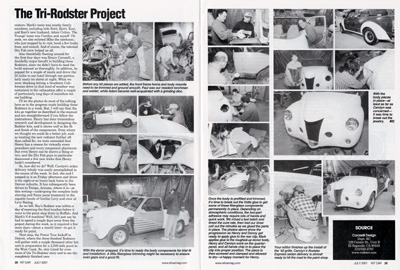

The plan was for three build teams to convene in Buffalo, Oklahoma, in late January 2001 and spend a week transforming three donors into hot rods -- two roadster versions and a sedan delivery -- minus paint, of course. Buffalo was chosen because Ray's business, Dry Fab, is housed in an old Chevy dealership that just happened to have plenty of empty, heated space in which we could all work. All three kits were delivered there, and the Dry Fab crew collected all the hardware, special tools, paint, and miscellaneous goods needed to complete all three Rodsters.

Now, Buffalo is not what you'd call a big town, especially considering the Greyhoud bus doesn't even stop there anymore and the stoplight was turned off some time ago. It's quite a friendly town up there in the panhandle, however, and word of our project got around quickly. Ray's shop became quite an attraction for local visitors. It was alternately described as everything from a chop shop, to the Rodster production line, to an Amish car raising. We even made the newspaper and were graciously welcomed at restaurants in two towns and a motel in Woodward, Oklahoma, as we contributed generously to the economy. We nearly cleaned out the True Value Hardware store of rattle cans and drill bits.

Dry Fab is a metal fabrication business specializing in oil and mining pipelines. As such, it's staffed with talented metal fabricators, welders, and craftsmen and is loaded with some of the coolest big tools you can imagine. It also houses a well-stocked hardware section, all of which contributed greatly to our project, particularly the skilled guys who went well beyond helping. Henry designed the Rodster kit to be able to be assembled at home with minimal tools, but items such as plasma cutters, MIG welders, hydraulic shears, metal brakes, pneumatic nibblers, air riveters -- and the talented guys who use them every day -- were most welcome.

We roamed among the three donor cars to help as we could. After one team completed a task, we went on to help the other two accomplish the same procedure. In a kind of training exercise for Mark's Wiley Engineering employees, the Tri-Rodster Project -- as he called it -- was set up on a project management Gantt flowchart and each step on the three cars was timed and logged. If you're interested in following along on the whole project, log onto www.trirodster.com and enjoy.

Ray's Dry Fab team consisted of son-in-law Paul, son Donny, and lots of frequent visitors. Mark's team was mostly family members, including kids Kent, Kerri, Kaci, and Kaci's new husband, Adam Cotton. The Youngs' team was Carolyn and myself. Oh yeah, we also enlisted Mike the mechanic, who just stopped by to visit, bend a few brake lines, and consult. And of course, the talented Dry Fab crew helped us all.

Also thankfully floating around for the first four days was Henry Caroselli, a decidedly major benefit to building these Rodsters, since we didn't have to read the build manual as thoroughly. In addition, he popped for a couple of meals and drove the 35 miles to our hotel through one particularly nasty ice storm at night. What we were thinking letting a Southern Californian drive in that kind of weather was testament to the exhaustion after a couple of particularly long days of marathon kit car building.

I'll let the photos do most of the talking here as to the progress made building three Rodsters in a week. But, I will say that the kits go together as described in the manual and are straightforward if you follow the instructions. Henry has done tremendous research and development in designing the Rodster kits, and it shows well in the fit and finish of the components. Even where we thought we could do a better job, such as locating the new radiator further aft than called for, we were reminded that Henry has a reason for virtually every procedure and every component placement. But even Henry can be shown a thing or two, and the Dry Fab guys in particular discovered a few new tricks that Henry hadn't considered.

So, how did we do? Well, Carolyn's sedan delivery rebody was easily accomplished in the course of the week. In fact, she and I jumped in it on Friday afternoon and drove it the eight-or-so hours back home to the Denver suburbs. It has subsequently been driven to Tempe, Arizona, where it is -- at this writing -- undergoing the complete body shaving and flame paint treatment in the capable hands of Gordon Levy and crew at Levy Racing.

As we left, Ray's Rodster was within a day of receiving the final touches before it went to the paint shop there in Buffalo. And Mark's V-8 machine? Well, let's just say he had to spend a couple days away from the project during the week, so it required a few more days -- about a month later -- to get it ready for paint.

Next stop, the Power Tour kickoff in Detroit, where the three finished Rodsters will gather with a couple thousand other hot cars in preparation for a 2,500-mile jaunt to the West Coast. So, stay tuned for even more of the Tri-Rodster story and to see the completely finished cars.